15th November 2018

The most common cold chain breaches – and what to do about them

Cold Chain

Breaches in the cold chain can quickly lead to a degradation of product quality and safety. Here we offer best practice advice for avoiding ‘thermal abuse’.

There’s that phrase often used in reference to the cold chain: that it’s only ever as strong as its warmest link. The challenge of course is that there exist many potential ‘warm links’ to concern suppliers, carriers, and retailers.

In effect these relate to each activity where a product is ‘touched’ – across multiple storage and transport stages. Each activity introduces the risk of product degradation, but before we look at ways to reduce this risk, let’s briefly explore the contributing factors.

At the supplier: starting at the right temperature

Problems may arise as early as the supplier, and the condition of any product emerging from warehouses that are not adequately pre-cooled prior to collection.

Product quality, safety, and shelf life can all be compromised if this doesn’t happen. For the transporter, a lack of pre-cooling also places the emphasis on them bringing the temperature of the products down – which takes time and costs energy.

Best practice certainly suggests that ‘successful temperature control starts at the beginning with the supplier’.

Loading and packaging: maintaining suitable airflow

The next challenge to address is the way products are stacked inside a vehicle, and the impact this has on air-flow.

It’s always good to remind ourselves that refrigerated transport is not about lowering the temperature as much as it is about removing heat. To do this requires unobstructed airflow throughout a trailer’s body.

A lack of such unrestricted airflow can quickly lead to:

- Hotspots – where poor flow can create pockets of heat damage

- Short-cycling – where discharged air is unable to travel the full length of the trailer

- Top-freezing – where products placed too close to discharged air suffer frost damage

Transport: matching temperature to product

Another challenge is ensuring acceptable temperature ranges are applied to the products being moved.

For example, frozen foods need a range of between -23°C – -9°C whereas potatoes and tomatoes demand a milder 5.5°C – 12°C. The pressure is therefore on for logistics companies to understand the temperature sensitivity of the loads they carry – and many retailers can only hope that they do so.

Delivery: minimising the impact of door openings

Finally, the last ‘touch’ point is when the door to a trailer is opened. Even with the most efficient of operatives such an action allows warm air to rush in, thereby raising the inside temperature.

Door openings are obviously inevitable in the overall process, which in turn means the trailer requires a refrigeration unit that’s fit for the job.

From problem to solution

So we have our list of the main contributors to ‘thermal abuse’. The question now is what sound operational procedures exist to mitigate their effect?

Well, below you’ll find a range of helpful advice for ensuring products remain frozen, chilled, or somewhere nicely in between.

Rules and responsibilities

Let’s start at the warehouse. Here it’s vital to establish the right processes and agreeing areas of responsibility.

- For the supplier, that means ensuring all products are pre-cooled to correct transit temperatures before they’re allowed to leave the building.

- For the transport company, the container should always be of the same temperature as the product during the loading process.

- For the driver, it means pre-trip inspections including tests of the refrigeration unit, the actual temperature being achieved, and that sufficient fuel is available

Know your load

It’s also important that the driver is familiar with the load being moved. Not only does this help guarantee the right temperature range is set and agreed – it also aids with loading.

As previously mentioned, the act of loading should be completed in a way that promotes airflow. Best practice also dictates that the product packaging itself should be designed with one eye on facilitating ‘clean’ airflow.

Container talk

As for the trailer itself, its condition can have an immediate impact on product quality. That’s why drivers should be encouraged to inspect trailers for air-leakage and condensation, as a way of spotting any potential ‘thermal breaks’.

It’s also recommended that a defrost is conducted half an hour after loading to clear the evaporator coil in the refrigeration unit, thereby ensuring maximum cooling performance.

Final considerations

All of which leaves us with two final points:

- Finding the correct temperature setting – here the driver can rely on various lists made available by customers, industry standards, and government bodies. Or they can rely on technology such as Thermo King’s Optiset product – that automatically sets the right temperature based on the goods selected from the menu list.

- Overcoming door openings – where the simple answer is you can’t! However, you can compensate for any drop in temperature by using the right refrigeration unit for the task at hand based on cooling capacity (the more frequent a door is expected to open, the higher the required capacity).

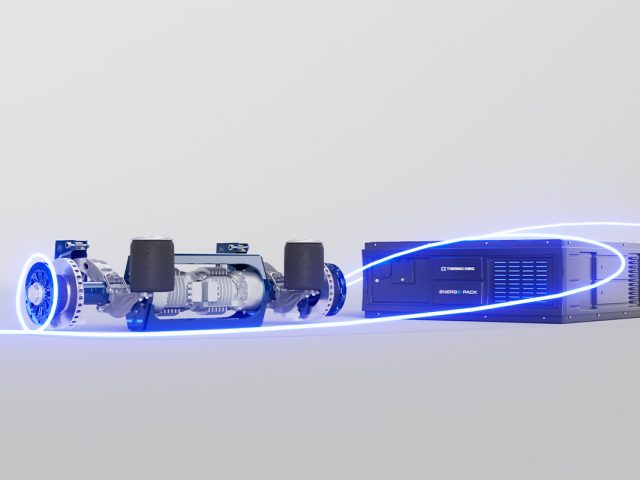

Mastering the cold chain

To help you achieve best practice in the cold chain Thermo King offers an extensive range of dependable refrigeration products – all installed and supported by our international dealer network. Best practice videos on managing the cold chain, air flow, and temperature setting are also available. For more information visit europe.thermoking.com/best-practices